|

| 12.05.2006: Headlights and grille |

|

The headlights and the grille go first. The broom is retired as a hood

prop rod, and replaced with an old 9-5 sway bar.

|

|

| 12.05.2006: Bumper and airbox |

|

The lower protective shields and the bumper come off to allow the access

to the intercooler. The airbox is now in the open, so that gets removed too.

|

|

| 12.05.2006: Intercooler and pipes |

|

Next, the old intercooler and pipes. Since all of this will go to another

car (which then gets sold), I've removed the turbo silencer while it's

exposed. The new owner should thank me for it ;].

|

|

| 13.05.2006: Exhaust system |

|

The stock exhaust system: downpipe with catalitic converter, flex pipe,

middle section with resonator, and rear muffler.

|

|

| 15.05.2006: Engine support |

|

Engine support installed. Time to disconnect the rear engine mount, detach

the shifter linkage, unbolt and lower the front subframe.

|

|

| 15.05.2006: Transmission |

|

The transmission is drained of oil and removed from the car.

[more...]

|

|

| 20.05.2006: Engine out |

|

The engine being removed out of the car.

[more...]

|

|

| 20.05.2006: On the stand |

|

Engine out, secured on a stand.

|

|

| 21.05.2006: Throttle body inlet pipe |

|

A ported throttle body inlet pipe: before and after.

|

|

| 22.05.2006: B234R |

|

A replacement 2.3L turbo engine from a 1996 Saab 9000 Aero.

|

|

| 25.05.2006: Engine stripped |

|

The old engine is stripped of all accessories, oil pan cracked open.

|

|

| 28.05.2006: Timing cover off |

|

The 2.0 with timing cover and end plate removed. On its way into storage.

|

|

| 28.05.2006: Out of the trunk |

|

The 2.3 is out of the trunk, the accessories will come off shortly.

|

|

| 28.05.2006: Ready for disassembly |

|

The replacement engine is stripped and mounted on a stand.

Ready for final disassembly.

|

|

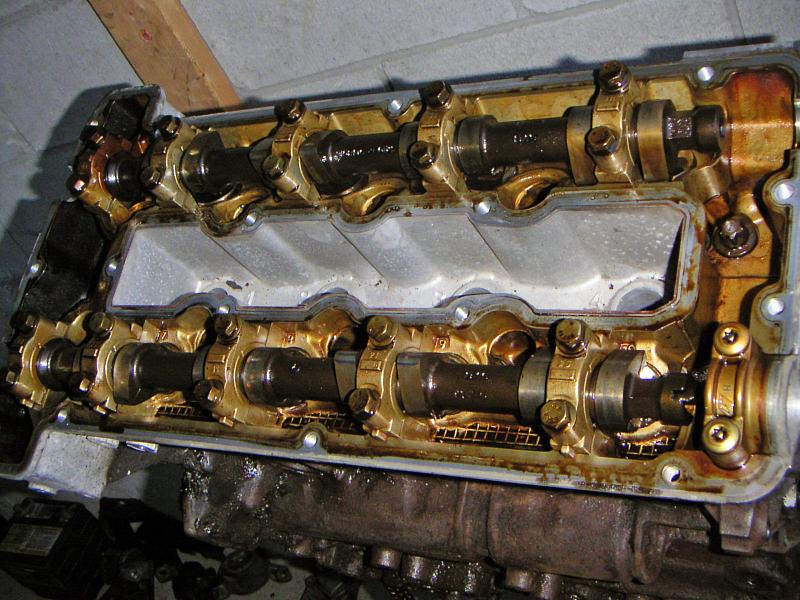

| 01.06.2006: Camshafts |

|

Valve cover off, no sludge, everything looks nice and clean.

|

|

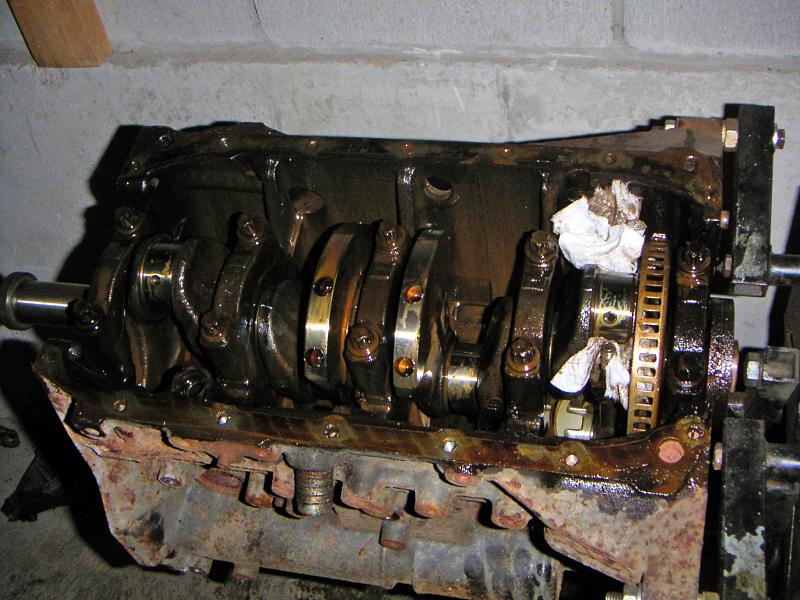

| 01.06.2006: Crankshaft |

|

Crankshaft and piston removal. The paper towel pieces are wrapped around

the bolts on the piston rod to prevent them from scratching the crankshaft.

|

|

| 02.06.2006: Out to rebuilder |

|

The engine on the way to the rebuilder to have everything cleaned and polished.

|

|

| 07.06.2006: Engine parts rebuilt |

|

Back from the rebuilder. Parts cleaned, cylinders honed, head polished.

|

|

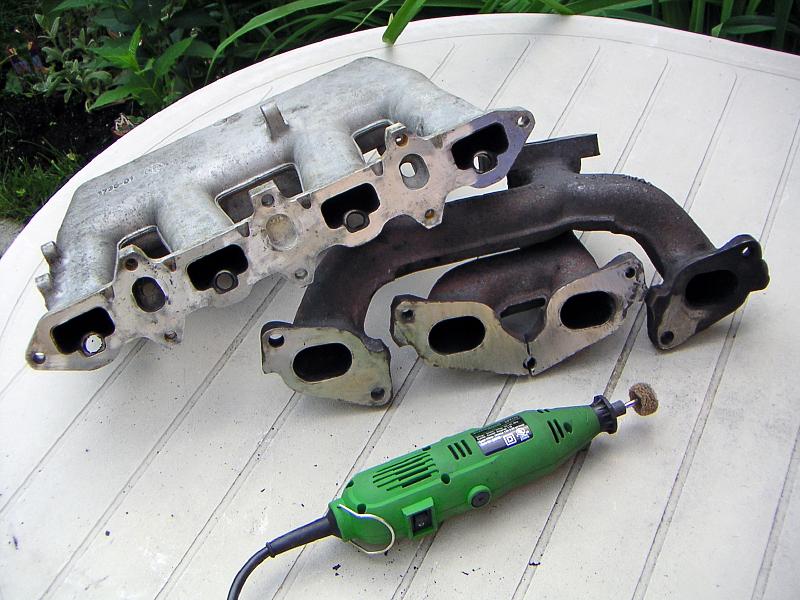

| 08.06.2006: Manifold cleaning |

|

Abrasive Dremel buffing wheels make it easy to clean manifold flanges.

Unfortunately, they wear out too fast.

|

|

| 08.06.2006: Firewall cut |

|

Another use for your favourite rotary tool: cutting a hole in the firewall

for the hydraulic clutch.

|

|

| 16.06.2006: Parts |

|

A big parts order from eEuroparts

just landed at my door in two large boxes.

|

|

| 18.06.2006: Cylinder head |

|

The head is assembled with new seals and refreshed valves.

[more...]

|

|

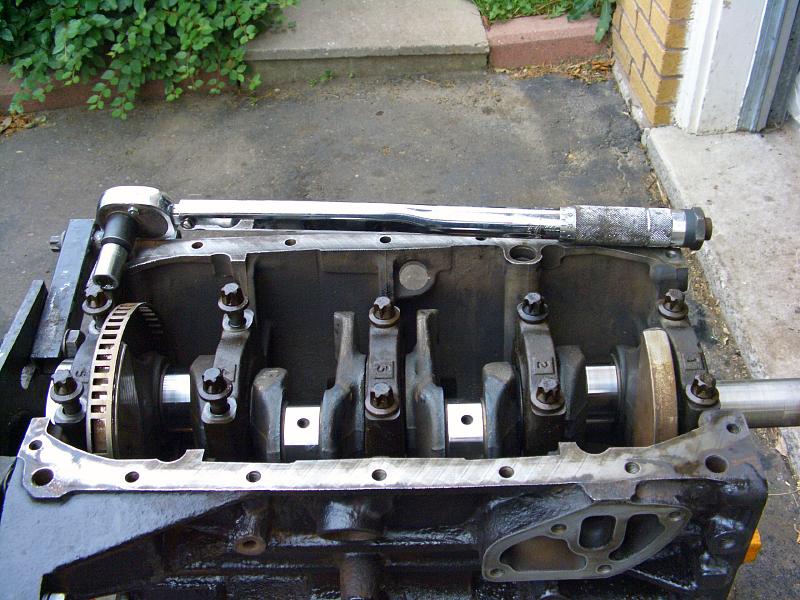

| 21.06.2006: Engine block |

|

Crankshaft and pistons are in with new rings and bearings.

[more...]

|

|

| 04.07.2006: Engine |

|

This starts to look like an engine again now.

[more...]

|

|

| 09.07.2006: Engine assembled |

|

The engine is assembled and ready to go in.

[more...]

|

|

| 10.07.2006: Installation |

|

Engine installation in progress.

[more...]

|

|

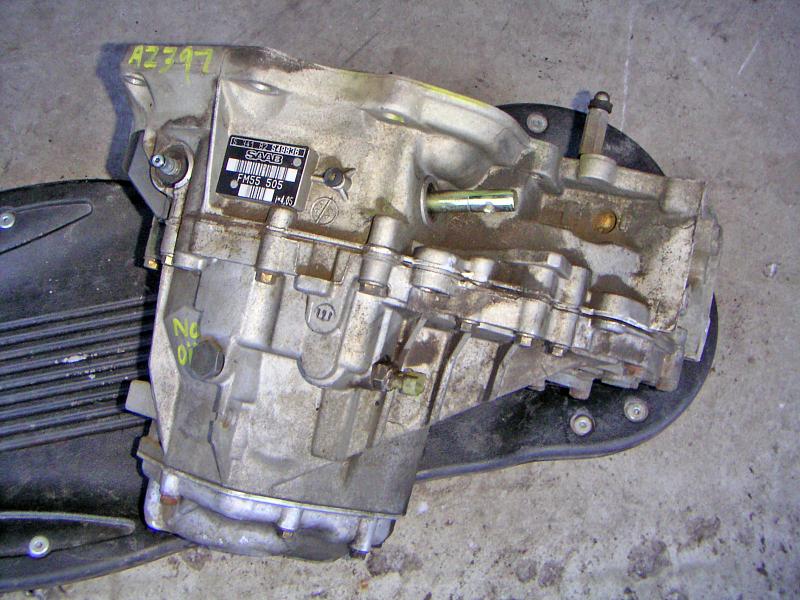

| 10.07.2006: Transmission |

|

A low mileage gearbox from a 1999 Saab 9-3 -- stronger, smoother,

easier to shift.

|

|

| 10.07.2006: SPEC clutch |

|

A kevlar stage2 clutch from SPEC and a Viggen pressure plate to hold the power.

|

|

| 15.07.2006: Engine in |

|

Installed and running.

|

|

| 18.07.2006: Delivery pipe |

|

One of MP Performance leftover delivery pipes. The fit was problematic,

but all worked out in the end.

|