| 08.04.2006

Original condition

The summer's near, and here's a great way to celebrate it:

a 1995 Saab 900SE turbo convertible. The car came from a local auction,

with the body and interior in

surprisingly good shape.

Unfortunately, it was not that good mechanically. It needed work in

many areas, including the engine, transmission, suspension and soft top.

Therefore the goal of this project was to build a better Saab convertible.

|

| 06.05.2006

Interior

The work started with interior.

The seats and dashboard were removed, the side panels and carpeting

stripped. The next step would be to clean everything up and prepare for

soundproofing and audio upgrade.

|

| 09.05.2006

Chassis

Suspension removal. The front end is

up on stands, the wheels are off, and the front struts together with

suspension arms and calipers are being removed from the car. Then I find

that I need to fiddle with the soft top to get to the rear shock towers,

and finally the whole rear axle meets the floor.

|

| 12.05.2006

Powertrain

Powertrain disassembly. The headlights,

grille and bumper come off to allow the access to the intercooler. The

intercoler is then removed with all the pipes, and the airbox follows it.

The exhaust system is easy to remove as it's held together with only

rubber hangers and clam clamps. The gearbox gets unbolted from the engine

and lowered to the floor. And finally, the engine comes out with a help

of a friend and a 3-ton shop crane.

|

| 28.05.2006

Engine rebuild

The engine is being replaced with a

2.3L block from a Saab 9000 Aero. The replacement engine came from a

scrap yard, so it first gets stripped, disassembled and sent to an engine

shop for machining and polishing. All accessories and manifolds are

also refreshed and cleaned.

|

| 10.06.2006

Paint and finish

New finish for all kinds of parts: valve cover, engine block, suspension.

|

| 28.06.2006

Dmitry in the garage

All parts have finally arrived, and the assembly work begun. You can

see there's a space issue. The garage is pretty tight, so keeping all

the parts and tools around is a bit of a problem.

|

| 17.07.2006

Out in the sun

The car is out of the garage for the first time. Engine and suspension

installation finished, wheels and bumper on. The front seats are installed

temporarily so the car can be driven. Here's a

short

video [YouTube] of the car rolling out of the garage.

|

| 02.08.2006

Soundproofing

Soundproofing is the last step before the final interior assembly.

A layer of B-Quiet Ultimate sound deadening material is applied on the

inside of the door and the outer surface, footwells, floor and side panels.

|

| 08.08.2006

Audio upgrade

The stereo system is upgraded with a more powerful four-channel amplifier,

all new wiring, Infinity Reference component speakers in front doors and on

the dashboard, and larger speakers in the rear for increased bass output.

|

| 14.10.2006

Completed

A final shot of the car. It already covered about 5000 km since the rebuild.

There were zero problems (aside from this

suspension issue). The car established itself to be solid and reliable, easy to

drive in everyday traffic, and fast and capable when you want to have fun.

|

| 30.11.2006

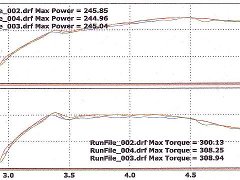

Dyno

A torque and horsepower graph from a Dynojet dyno, taken at ambient

22°C (71°F), 29.4 in-HG. The shop only had a small portable

fan, which limited the car's performance on the dyno. It only held

15-16 psi of boost instead of its usual 18-19 psi, and started to drop

off at just 4300 RPM. As the result, the top figures measured were 246

whp and 309 ft-lbs at the wheels. Accounting for a 12% drivetrain loss, it

gives 280 hp and 350 ft-lbs at the crank. The real world performance

in more favorable conditions is estimated to be around 300-310 hp.

|

| 20.04.2007

Roll Bar

A four-point roll bar built to

CASC-OR specifications.

I had to do this to make the car admissible to local driving events and

high performance driving schools. Fabricated by

CSC Racing - one of the best roll

cage builders in Ontario. It is removable, and fully clears the roof when

installed. The bar bolts to the floor and the torsion box, and only

requires the removal of rear interior panels to fit.

|

|