|

| 16.07.2005: Hub nut |

|

With the car still on the ground, remove the centre cap from the wheel and

loosen the hub nut using a 32 mm socket (a 1¼" will do) and a

breaker bar. Loosen the wheel bolts while you're at it too (17 mm socket).

|

|

| 17.07.2005: Rim |

|

Raise the car and remove the wheel. These little grease splatters on the

inside on the rim are a clear sign of the problem. The side where the

grease is concentrated the most can help locate the crack in the boot.

|

|

| 17.07.2005: Caliper |

|

Undo the hub hut completely. Remove the caliper (10 mm Allen socket) and

hang it onto something so no load is placed on the brake line.

|

|

| 17.07.2005: Tie-rod |

|

Clamp the tie-rod and undo the nut (18 mm socket). Use a gear puller to

separate the rod end. You may also remove the ABS sensor to clear the way

(5 mm Allen key).

|

|

| 17.07.2005: Control arm |

|

Disconnect the anti-roll bar link from the control arm. Use a 13 mm socket

on the nut and a 11 mm spanner on the top end.

|

|

| 17.07.2005: Rotor off |

|

Remove the index screw

(see here for

possible solutions if it gets stuck) and take the rotor off.

|

|

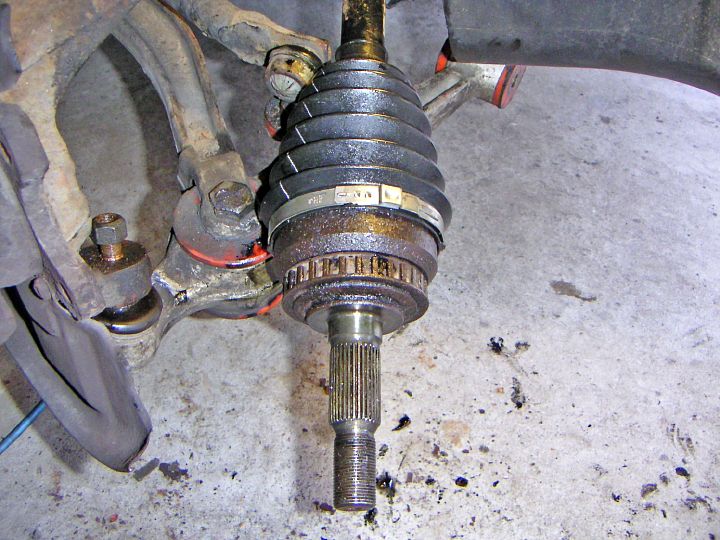

| 17.07.2005: Disconnected |

|

If you have a proper ball-joint separator (NOT a fork-type!), you can undo

the ball joint. I found it easier to unbolt the control arm from the

subframe instead (15 mm socket). Tilt the strut out of the way and pull

the axle out.

|

|

| 17.07.2005: Clamps |

|

Remove the old clamps from the boot with a chisel or a big screwdriver.

Slide the boot up the shaft and start removing the grease.

The joint is firmly seated on the driveshaft and secured by a snap ring.

|

|

| 17.07.2005: Joint removed |

|

Once you dig the ring from under the layer of grease, do you best to remove

it. I ended up pulling it out with vice-grips, which straightened it

completely (and thus destroyed). Gently tap the CV joint until it comes off

the axle.

|

|

| 17.07.2005: Boot |

|

This is where the crack in the boot was. It didn't seem big, and there

was enough grease to last for the next half a year until it all leaks out,

but I didn't want to take my chances.

|

|

| 17.07.2005: Disassembled |

|

Disassemble the joint. First, turn the inner part sideways to take

out the balls one by one, then remove the remaining parts.

|

|

| 17.07.2005: Cleaned up |

|

Clean everything thoroughly to wipe out all of the old grease. Do not

let the dirt to get into the joint from now on.

|

|

| 17.07.2005: New kit |

|

Here's the new boot kit from

eEuroparts. It contains a new boot,

two stainless clamps, a replacement snap ring and a tube of fresh grease.

|

|

| 17.07.2005: Boot on |

|

Put the boot on and inspect how the joint assembly connects to the axle.

|

|

| 17.07.2005: Packed |

|

Put the new snap ring into the joint so the angled ends are seated in the

opening in the star-shaped centre part, and fill the bearing with grease.

|

|

| 17.07.2005: Installed |

|

Gently tap the joint on until the ring clicks into the groove

in the shaft.

|

|

| 17.07.2005: Clamp |

|

Put the boot on. There are grooves in the joint body and the axle that

help you position the boot properly. Put the clamp on.

|

|

| 17.07.2005: Crimping |

|

If you don't have a specialized crimping tool, the job can be done with

a pair of thin Allen keys and the mighty vice-grips.

|

|

| 17.07.2005: Joint finished |

|

Put the second clamp on and inspect the boot.

|

|

| 17.07.2005: Axle installed |

|

Insert the axle into the hub.

|

|

| 17.07.2005: Control arm |

|

Bolt the control arm to the subframe (85 ft-lbs) then connect the anti-roll

bar link (8 ft-lbs). Clamp and tighten the tie-rod end (55 ft-lbs), install

the ABS sensor.

|

|

| 17.07.2005: Brakes |

|

Install the rotor and the caliper (87 ft-lbs). Bolt the hub nut on

reasonably tight. Put the wheel on (84 ft-lbs) and lower the car to the

ground. Tighten the hub nut to 214 ft-lbs.

|