|

| 21.01.2006: Battery |

|

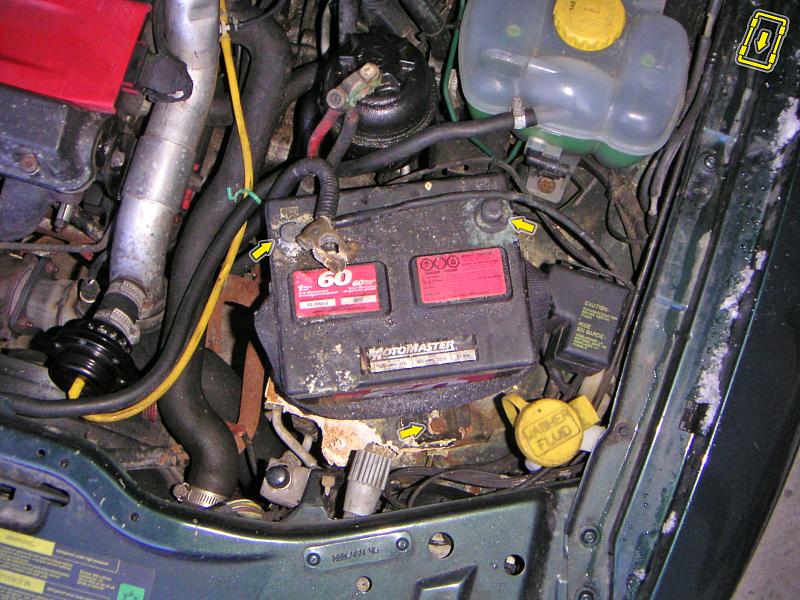

Disconnect both cables from the battery (negative first!). Unscrew the

13 mm bolt at the battery base.

|

|

| 21.01.2006: Battery base |

|

Lift the battery and store it in a safe place. Unbolt the battery

mounting plate (two 10 mm bolts) and remove it from the car.

|

|

| 21.01.2006: Delivery pipe |

|

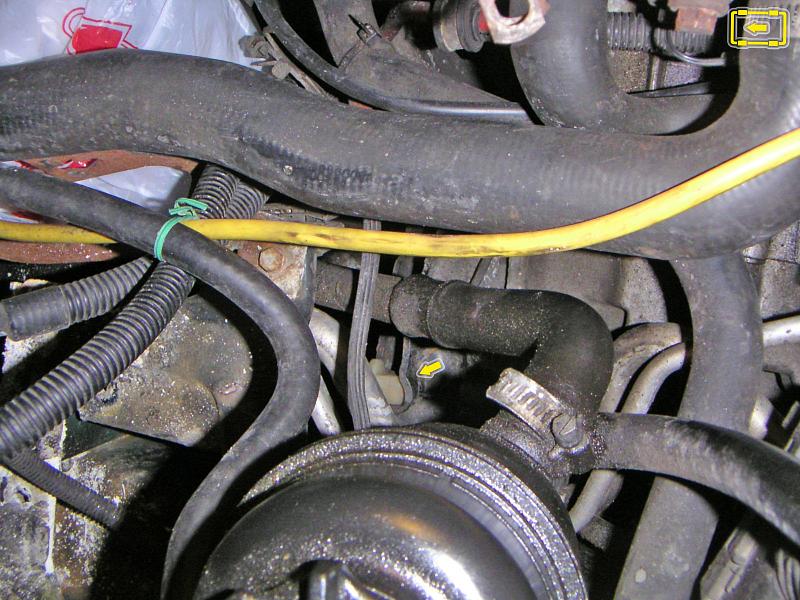

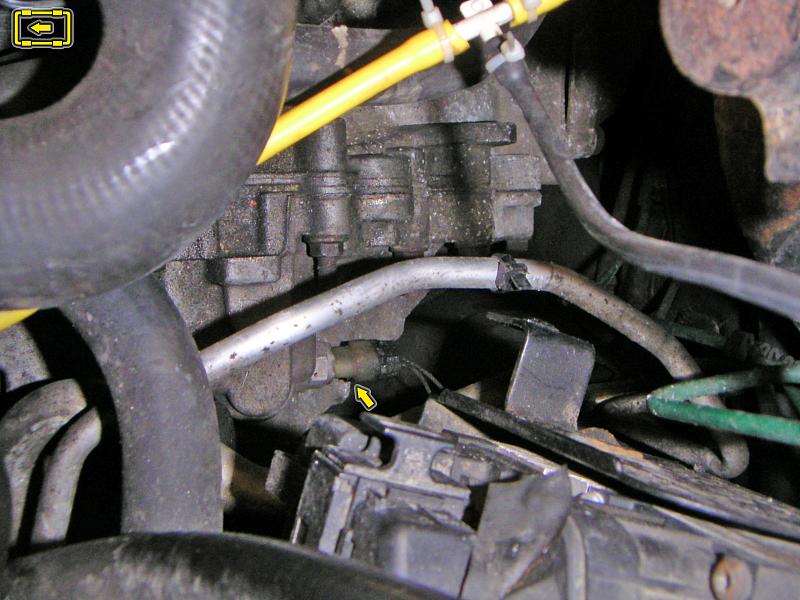

Release the hose clamp on the lower end of the delivery pipe.

Unhook the vacuum line from the bypass valve (as well as the return

hose if you have it).

|

|

| 21.01.2006: Delivery pipe |

|

Remove the hose clamp from the throttle body side of the delivery

pipe. Unbolt the pipe from the engine (13 mm wrench).

|

|

| 21.01.2006: Delivery pipe |

|

Remove the delivery pipe from the car. Plug the intercooler hose and

throttle body inlet to keep the dirt away.

|

|

| 21.01.2006: Fourth gear |

|

Move the shifter into fourth gear.

|

|

| 21.01.2006: Transmission lock |

|

Remove the plastic plug on top of the transmission and insert a thin

L-shaped Allen key to lock it in gear.

|

|

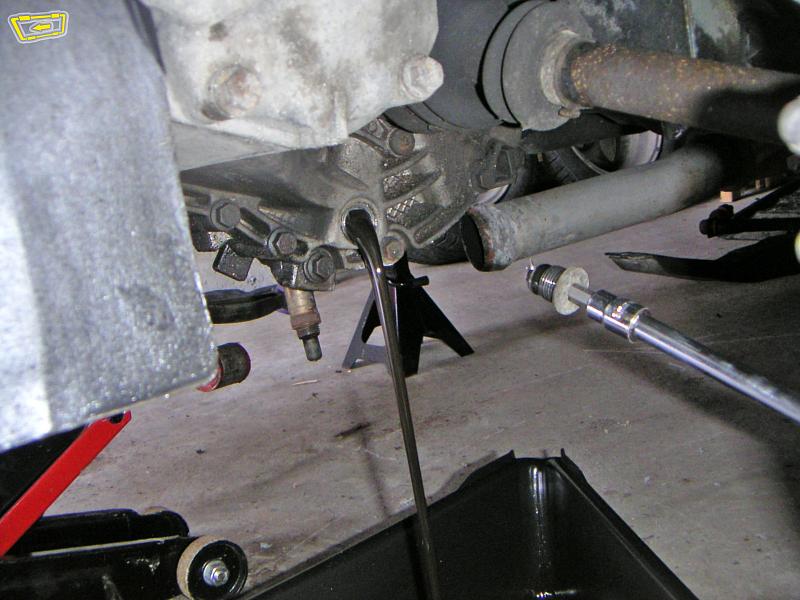

| 21.01.2006: Linkage |

|

Use a 13 mm socket with a long extention to loosen the nut on the

shifter linkage.

|

|

| 21.01.2006: Third gear |

|

Move the shifter into third gear position to separate the shifting rod

from the linkage.

|

|

| 21.01.2006: Cable |

|

If you have a cable clutch, unhook the cable from the lever on top of the

transmission. If it is hydraulic, pull the clip to detach the clutch line

from its nipple and quickly plug it to minimize fluid loss.

|

|

| 21.01.2006: Cable |

|

Pull the cable from its seat on the other end of the transmission.

|

|

| 21.01.2006: Reverse switch |

|

Unplug the reverse gear switch.

|

|

| 21.01.2006: Wheels |

|

Loosen wheel nuts (17 mm wrench).

|

|

| 21.01.2006: In the air |

|

Raise the front of the car, remove the wheels, take off the plastic shields

under the bumper.

|

|

| 21.01.2006: Brace |

|

Remove the subframe brace if equipped (11 mm socket for MP Performance

version).

|

|

| 21.01.2006: Exhaust joint |

|

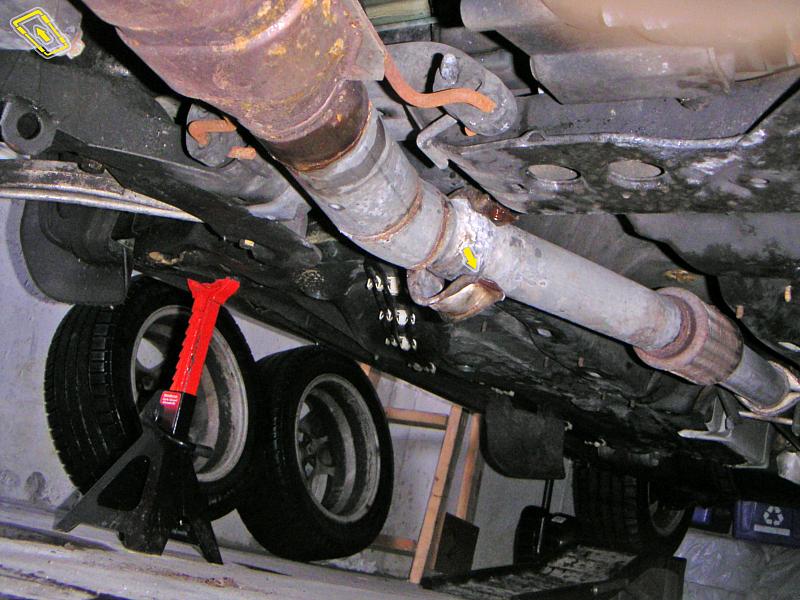

Unscrew the rear O2 sensor (22 mm crowfoot socket), remove the clamp

from the exhaust pipe (13 mm socket). Unbolt the two rear engine mount

nuts sitting in the round holes in the subframe (16/17 mm socket).

|

|

| 21.01.2006: Downpipe |

|

Unbolt the front O2 sensor (22 mm crowfoot) and detach the downpipe

from the turbo (three 13 mm nuts).

|

|

| 21.01.2006: Downpipe |

|

Unhook the rubber hangers and remove the downpipe from the car.

|

|

| 21.01.2006: Linkage |

|

Unbolt the linkage from the shifter rod on the transmission (13 mm socket).

|

|

| 21.01.2006: Linkage |

|

Detach the linkage support arm from the ball pin on the differential

housing (or pull it from the eye on the mount if you have an old-style

linkage).

|

|

| 21.01.2006: Linkage |

|

Remove the gearshift linkage from the car.

|

|

| 21.01.2006: Engine support |

|

Unbolt the rear engine mount from the subframe, install an engine support beam on the fenders, attach it to the lifting

hook on the head and pull up slightly to ensure it takes the weight

of the engine.

|

|

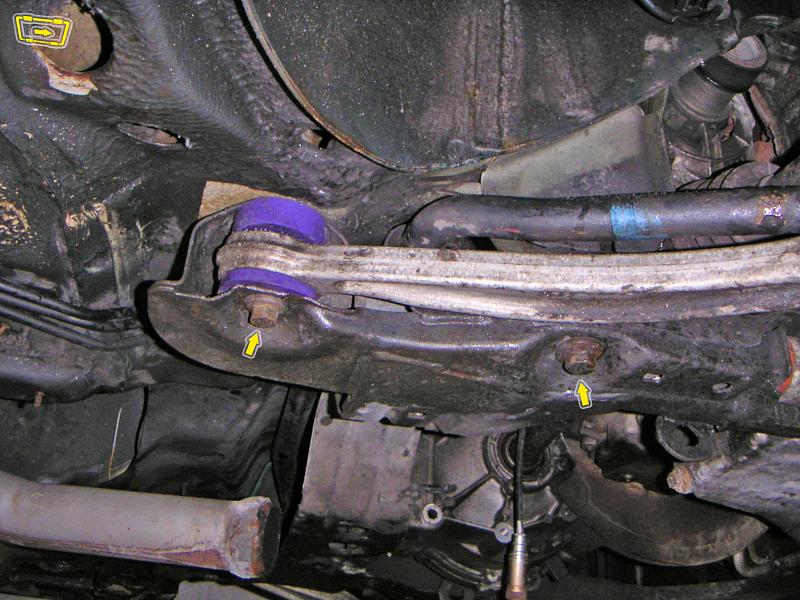

| 21.01.2006: Subframe bolts |

|

Start removing the subframe bolts. The rear bolts holding the stanchion

arms take a 16 mm socket, the middle ones are 18 mm.

|

|

| 21.01.2006: Subframe bolts |

|

The bolts in front have a 16 mm head as well. With all bols removed,

the subframe will be hanging on just the ball joints.

|

|

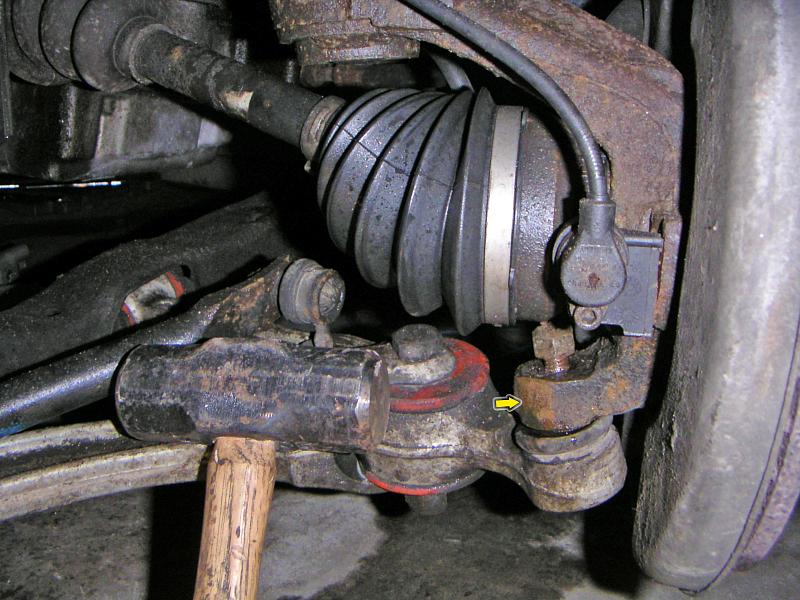

| 21.01.2006: Ball joint |

|

You can usually separate the ball joints by unscrewing the nut a bit, and

hitting the knuckle with a heavy hammer (the weight of the subframe helps

to release the ball joints).

|

|

| 21.01.2006: Jack |

|

If the ball joints cannot be defeated, unbolt the control arms from

the subframe. Jack it up so it doesn't drop to the ground right away.

|

|

| 21.01.2006: Subframe |

|

Lower the subframe to the ground and drag it away. In my case, I succeeded

in separating one ball joint, and unbolted the control arm on the other

side.

|

|

| 21.01.2006: Subframe bolts |

|

The subframe bolts left to right: rear, middle, front. Don't lose the

washers that go between the subframe and the body above the stanchion arms.

|

|

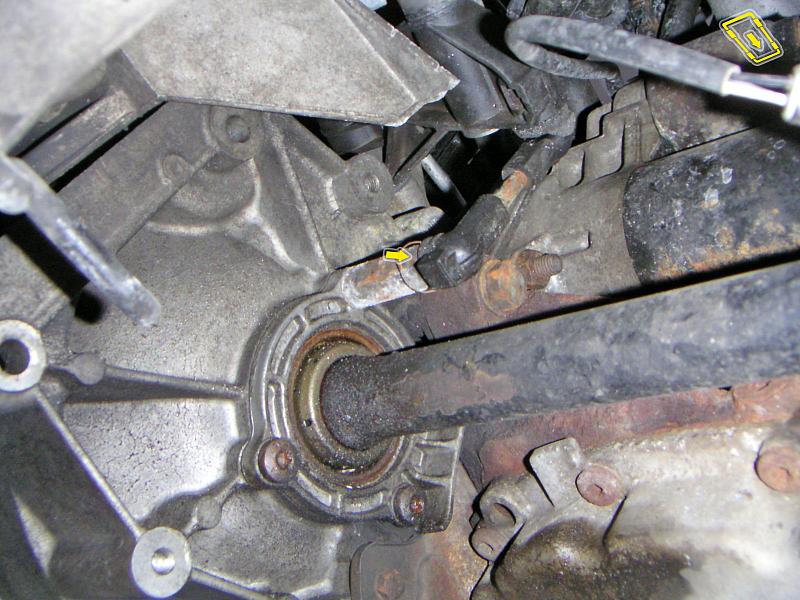

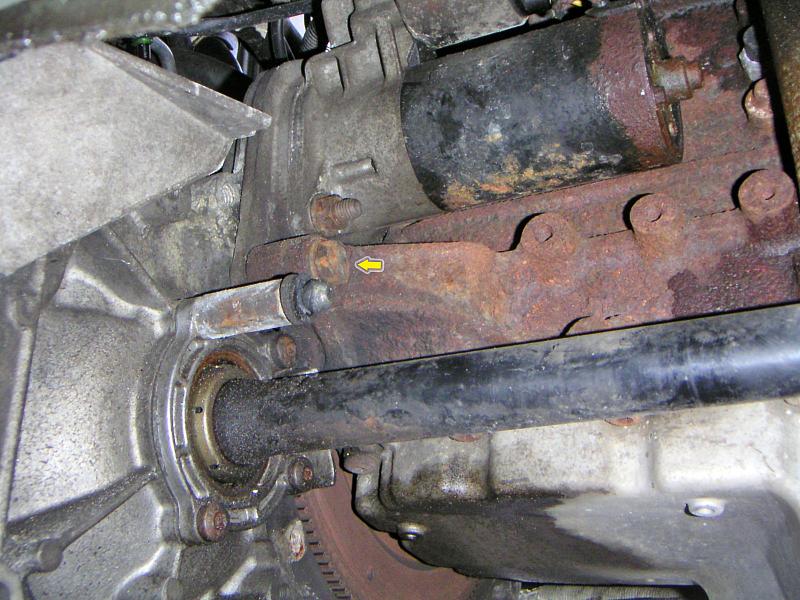

| 21.01.2006: Transmission oil |

|

With the subframe out of the way, it's now easy to remove tha drain plug

(8 mm Allen socket) and drain the transmission oil.

|

|

| 21.01.2006: Driveshaft |

|

Prop a wide flat chisel against the differential housing and push on the

other end to pop the driveshaft. It should slide right out.

|

|

| 21.01.2006: Driveshaft |

|

Suspend the driveshaft (or remove it completely if you unbolted the axle

nut).

|

|

| 21.01.2006: Flywheel cover |

|

Unbolt the flywheel cover at the bottom of the transmission

(two 11 mm bolts).

|

|

| 21.01.2006: Upper bolts |

|

Remove the three upper bolts attaching the transmission to the engine

(18 mm socket).

|

|

| 21.01.2006: Transmission mount |

|

Detach the small wire on the side of the transmission (13 mm socket).

Unbolt the transmission mount from the body (two 15 mm bolts), lower

the engine slightly to free up the mount.

|

|

| 21.01.2006: Mount bracket |

|

Unhook the big ground wire from the transmission (17 mm socket). Unbolt

the bracket from the transmission (and the mount itself from the

bracket if it helps to remove it).

|

|

| 21.01.2006: Rear bolt |

|

Remove the rear transmission bolt (18 mm socket).

|

|

| 21.01.2006: Lowering |

|

Lower the engine as much as needed to get a good access to the transmission.

|

|

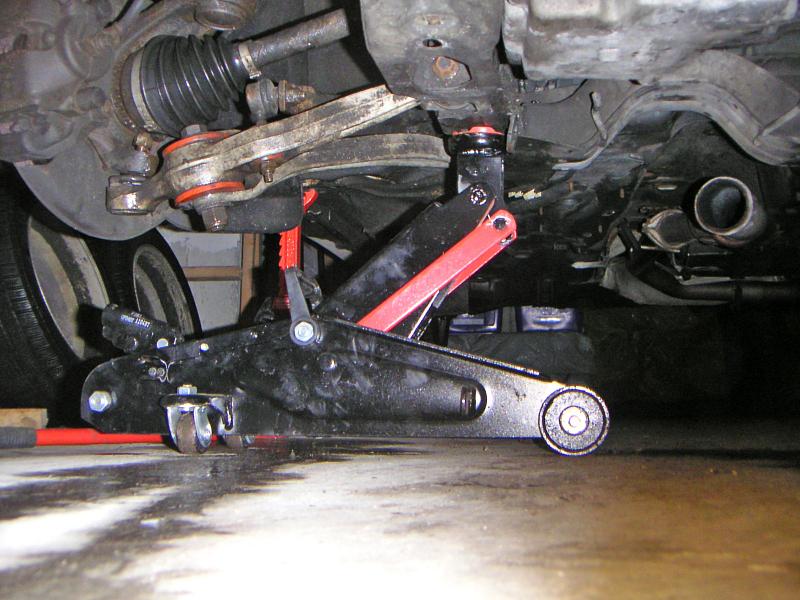

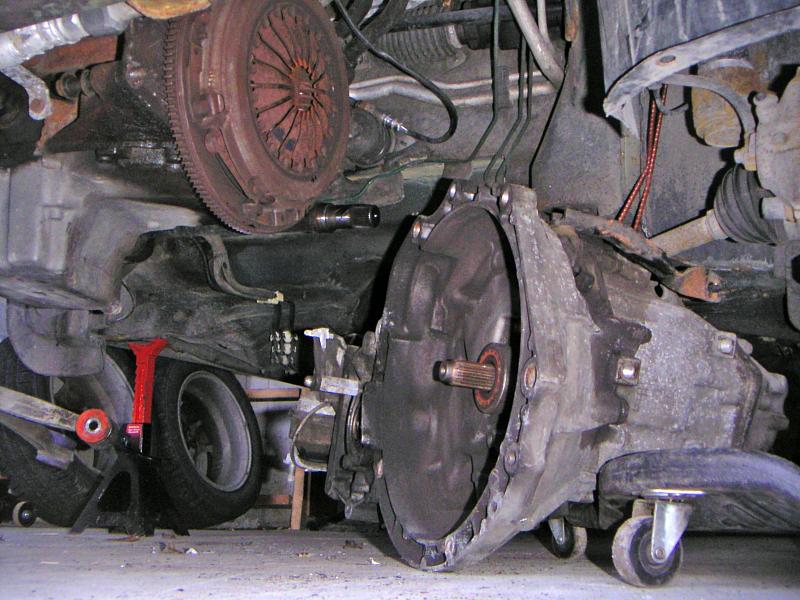

| 21.01.2006: Jacks |

|

If you don't have a specialized transmission jack, a couple of regular ones

will support it from below. Just make sure it's balanced right so it won't

slide sideways and fall to the ground when you detach it from the engine.

|

|

| 21.01.2006: Front bolt |

|

Undo the last bolt holding the transmission. If you were lucky enough to

detach a control arm from the subframe, you can use its bolt as a guiding

pin in place of the shorter original bolt.

Gently pry the transmission away from the engine.

|

|

| 21.01.2006: Transmission down |

|

The main shaft will slide right out, but the intermediate shaft might not

want to separate, so in the worst case you'll have to unbolt it from the

block under the alternator. Lower the transmission to the ground.

|

|

| 24.06.2006: Crane |

|

A shop crane makes transmission removal much easier. Older gearboxes

have one hole for a lifting eye, newer ones might have two.

|

|

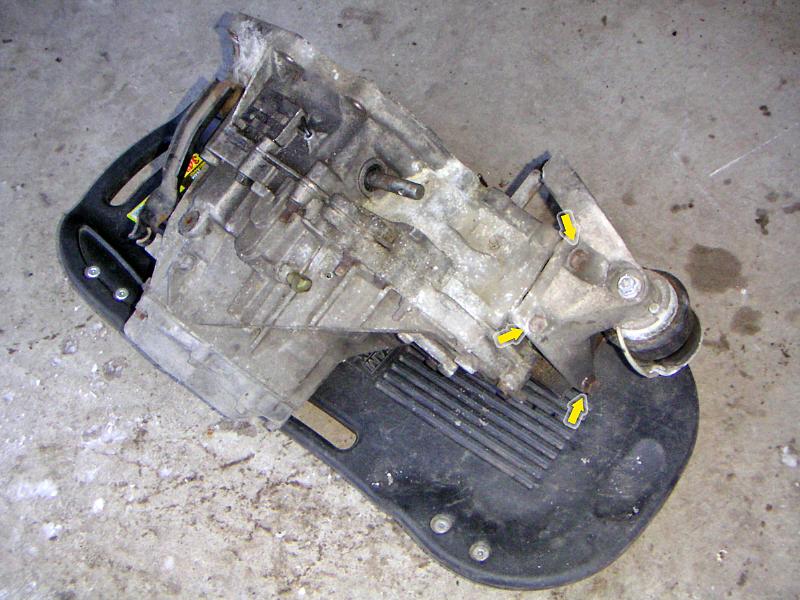

| 21.01.2006: Transmission |

|

Move the transmission away and unbolt the rear engine mount bracket if

you're planning to transfer it to a new gearbox.

|

|

| 21.01.2006: Pressure plate |

|

The flywheel will turn a bit, so you might need to came up with a way to

hold it in place while unbolting the pressure plate (six 12 mm bolts).

|

|

| 21.01.2006: Flywheel |

|

If the flywheel is visibly scratched or scored, or has cracks in it, you

need to remove it from the engine and take to a machine shop for

resurfacing.

|

|

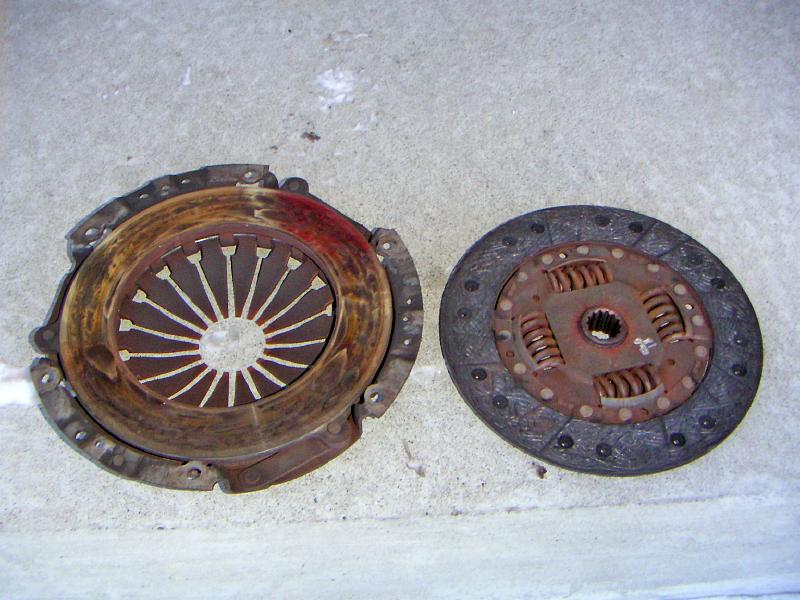

| 21.01.2006: Old clutch |

|

The poor clutch shows painful signs of trying to hold the stage3 power.

|