|

| 23.05.2005: Grille |

|

Raise the front of the car and open the hood. Remove the grille by

detaching two tabs on top.

|

|

| 23.05.2005: Blinker |

|

Undo the Torx T25 screw on the turn signal assembly, remove the housing and

unplug the wires.

|

|

| 23.05.2005: Headlight |

|

Remove the headlights (three Torx T25 screws). Unplug the wires, use a flat

screwdriver to release the locking tab on the harness.

|

|

| 23.05.2005: Wiper |

|

Lift the covers over the nuts on the headlight wiper arms and

remove the arms (8 mm socket). Detach the washer fluid hose from the bumper (there is

a couple of metal tabs holding it).

|

|

| 23.05.2005: Lower shields |

|

Remove the plastic shields from below. Each side is held by half a dozen

screws with a 8 mm hex head.

|

|

| 23.05.2005: Foglight |

|

Unplug the wires from the foglights.

|

|

| 23.05.2005: Sensor |

|

Detach the temperature sensor under the bumper. That horrible rusty thing

is the license plate holder.

|

|

| 23.05.2005: Screw |

|

Remove the Torx T25 screw under the fender (one on each side).

|

|

| 23.05.2005: Bumper bolts |

|

Undo two long bumper bolts located next to the headlight wipers (16 mm

socket).

|

|

| 23.05.2005: Bumper |

|

Pull the bumper forward and remove it from the car. Mind the sides of the

bumper cover while pulling: there are latches on each side that you need

to release.

|

|

| 23.05.2005: Intercooler |

|

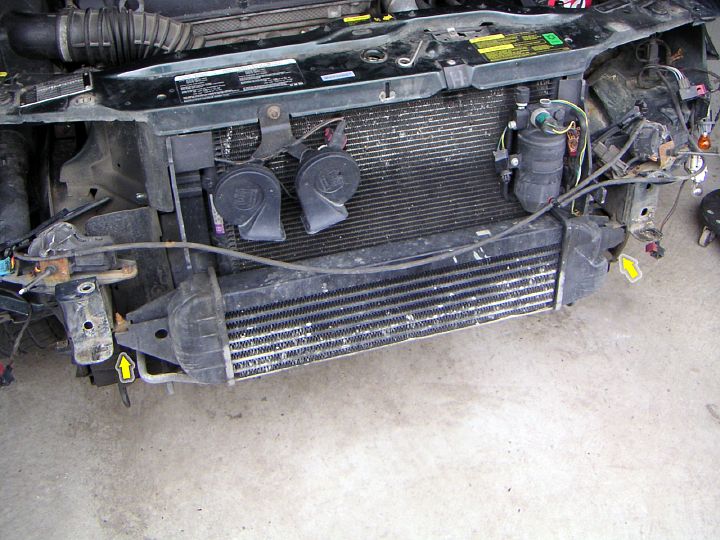

The intercooler is held by two long (and likely rusty) bolts. Use a

10 mm socket to remove those. Both hoses are attached on the driver's side,

the clamps can be released through the headlight opening with either

a 7 mm socket or a flat screwdriver (and a lot of rust solvent).

|

|

| 23.05.2005: Old intercooler |

|

Remove the intercooler from the car. Detach the hoses from the delivery

pipe and the turbo.

|

|

| 23.05.2005: Old vs new |

|

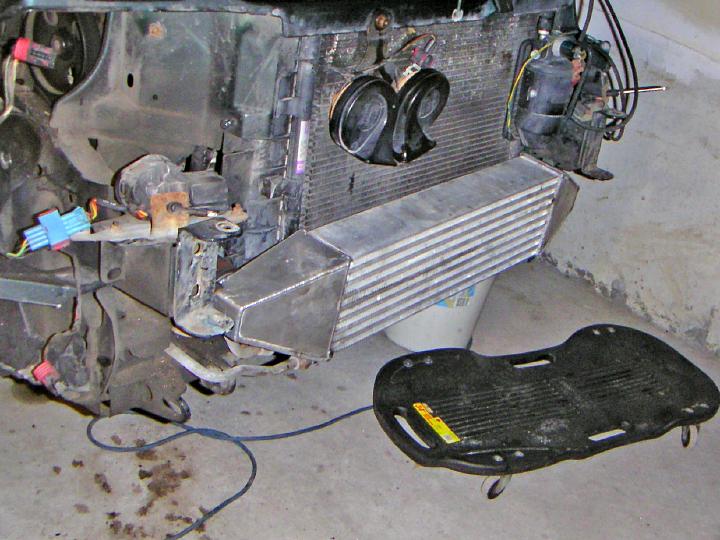

The old intercooler was a two-pass design, the new one is a cross-flow.

|

|

| 23.05.2005: Old vs new |

|

The upgraded intercooler core is made by Spearco and has a 3"x7" cross

section with a flow area of 5.30 square inches. This is 60% more than a

cross-flow Viggen intercooler has, and 4 times more than my base unit.

There are also 5 times more fins for a much greater cooling capacity.

|

|

| 23.05.2005: Old vs new |

|

The end tanks are made by MP. You can see an extra weld spot: this was

a discounted defective unit. I had to take it to an alloy welder for

repair first. We've found four pinholes in the welds. The regular units

should not have these problems, but it never hurts to do a pressure test.

Also check for metal shavings in the end tanks: I had a lot of those.

|

|

| 23.05.2005: Old vs new |

|

The newer intercoolers MP sells now have additional grooves machined on

the inlet pipes to help secure the hoses better. Mine didn't have that,

and the pipes were unequal length, but then again, I knew what I was

getting, and it's hard to complain considering the discount they offered.

|

|

| 23.05.2005: Lower radiator hose |

|

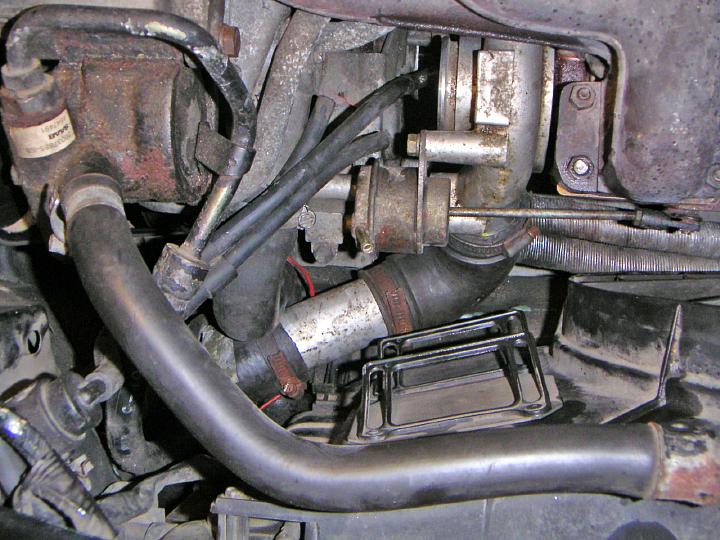

The 900 models have an older lower radiator hose that gets in the way of

the intercooler inlet hose. It has to be replaced by a new design (Saab

part #4963872).

|

|

| 23.05.2005: Draining coolant |

|

With the intercooler removed, you now have the access to the radiator

drain plug. Use a piece of aluminium foil to form a trough gutter and

drain the coolant into a clean bucket so you can reuse it later (assuming

your coolant does not require replacement yet).

|

|

| 23.05.2005: 900 vs 9-3 |

|

Here's the old hose next to the new style hose provided by MP. They

supply used hoses, and unfortunately this one had a crack on the back.

I've noticed it too late and had to reinstall the old hose since it was

a holiday and the dealership was closed.

|

|

| 23.05.2005: Coolant tank |

|

To not make my coolant drain a total waste of time, I cleaned the coolant

expansion tank (it looks rather dirty on this picture). A quarter cup of

rice, some soap water and 10 minutes of vigorous shaking made it shine like

new! If you do that, wash it well: you don't want any rice in your coolant

pipes ;).

|

|

| 23.05.2005: Old inlet pipe |

|

Normally, the intercooler is supplied with Viggen hoses which are almost

a direct fit. The custom made piping would've been even better.

Unfortunately, I had neither, since my intercooler didn't come with any,

and the stores were closed. So I decided to make the most of the stuff

I had.

|

|

| 23.05.2005: Test fit |

|

I had one extra elbow that helped to form the inlet section.

The test fit looks promising.

|

|

| 23.05.2005: Inlet hose |

|

The intercooler is put in place and the turbo hose is attached. This

actually looks better than the Viggen hose, as the Viggen elbow forms

a nasty bend on the T25 turbo, because the T25 is angled differently.

And there's enough clearance even with the original radiator hose.

|

|

| 23.05.2005: Radiator fan |

|

The new hose did not fit with the radiator fan frame, so I had to cut

a corner of the frame off.

|

|

| 23.05.2005: Fan installed |

|

The fan is attached with two screws at the top. Everything seems to

fit well. Make sure all clamps are very tight, especially if you used soap

or another lubricant to put them on. You don't want any of those to come

off on the road.

|

|

| 23.05.2005: Hose |

|

This is the hose from the intercooler to the delivery pipe. It had to

be extended an inch and a half. The clamps are easier to reach from under

the car.

|

|

| 05.11.2005: New hoses |

|

This is an updated hose arrangement used with a Mitsubishi TD04 turbo

(aka "Viggen turbo").

|

|

| 05.11.2005: Turbo pipes |

|

The compressor outlet on TD04 is angled differently, which allows

for a shorter hose.

|

|

| 23.05.2005: Zip ties |

|

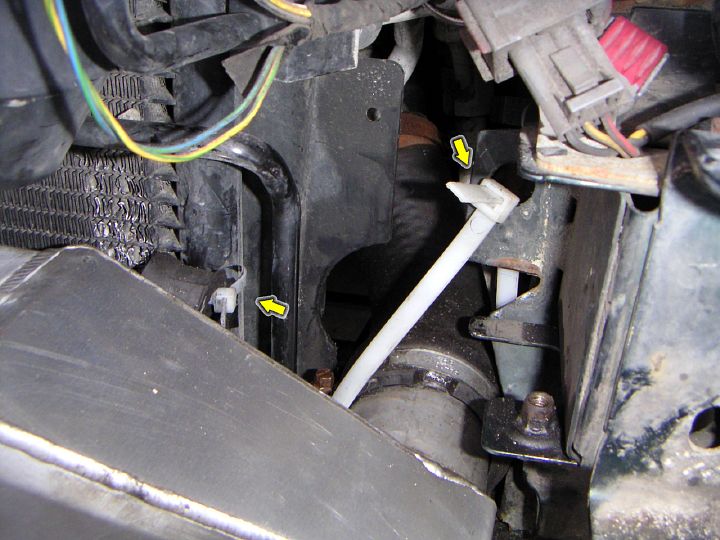

The intercooler is not bolted on like the old unit, but it's held by the

hoses quite firmly and is not going anywhere. I added strong zip ties on

each side, as well as a couple of rubber strips to prevent it from rubbing

against the radiator.

|

|

| 05.11.2005: No bumper |

|

A view of the intercooler with the bumper removed.

|

|

| 05.11.2005: Bumper on |

|

The bumper is a rather close fit. Leave the intercooler sticking out

too far, and it will rub against the bumper rail.

|

|

| 23.05.2005: Coolant |

|

Time to fill the coolant.

|

|

| 23.05.2005: Installed |

|

Install the lower shields, headlights and grille. The only

sore spot left is my rusty license plate holder, which also blocks the

intercooler.

|

|

| 23.05.2005: License plate |

|

The finished install: the plate has been replaced and attached higher, and

the intercooler is seen through the opening in the bumper.

|