|

| 10.07.2006: Lowering |

|

Carefully lower the engine into the engine bay. Make sure it clears

everything sticking out on its way down.

|

|

| 10.07.2006: Engine mount |

|

Align the engine so the passenger side mount can be attached to the body

and tighten the bolts to 54 ft-lbs.

|

|

| 10.07.2006: Support bar |

|

Install the support bar across the fenders and take the weight off the

crane. The engine will now rest on the passenger side mount and the

support bar.

|

|

| 10.07.2006: Transmission |

|

Now is the good time to

install the transmission.

It can be done at a later stage, but it's easier without having coolant

hoses and wires in the way. It also allows to install the subframe right

away and get rid of the support bar.

|

|

| 10.07.2006: Steering pump |

|

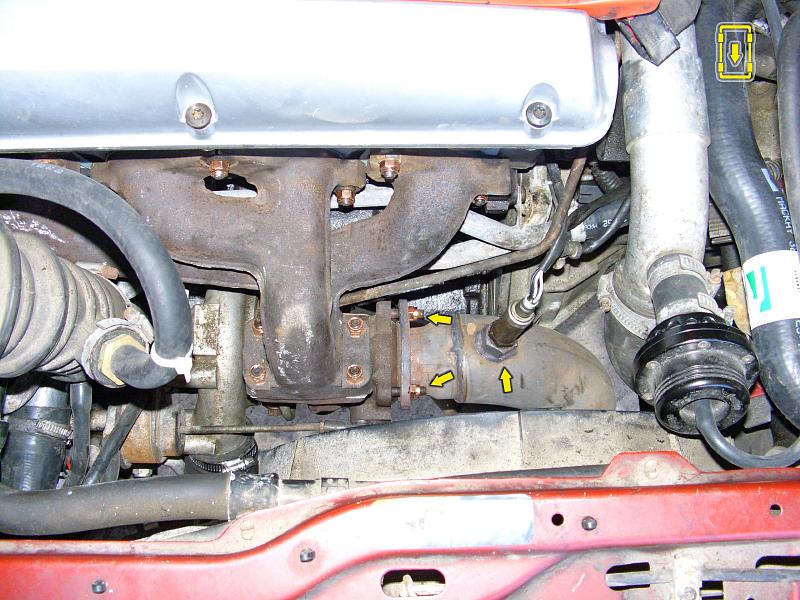

Attach the steering pump with three 13 mm bolts. The bolt location is rather

awkward, and in most cases there's only enough room for a 1/6 or even 1/12

turn of a spanner at a time.

|

|

| 10.07.2006: A/C compressor |

|

Bolt the A/C compressor to the engine (three long 16 mm bolts). Plug

the A/C clutch wire into its connector on the radiator. Attach oil cooler

lines to the oil filter housing (22 mm wrench).

|

|

| 10.07.2006: Belt |

|

Lock the tensioner using a long ½" extension and a 2 mm pin

and fit the accessory belt. The picture shows a short belt configuration

with the middle idler pulley bypassed.

|

|

| 10.07.2006: Airbox |

|

Install the airbox and connect the ribbed hose to the turbo inlet pipe.

|

|

| 10.07.2006: BPC |

|

Attach the boost pressure control valve to its proper location (two T25

screws) and route the cable around the airbox.

|

|

| 10.07.2006: ECU harness |

|

Feed the ECU harness back through the hole in the firewall and plug it

with the rubber grommet.

|

|

| 10.07.2006: ECU |

|

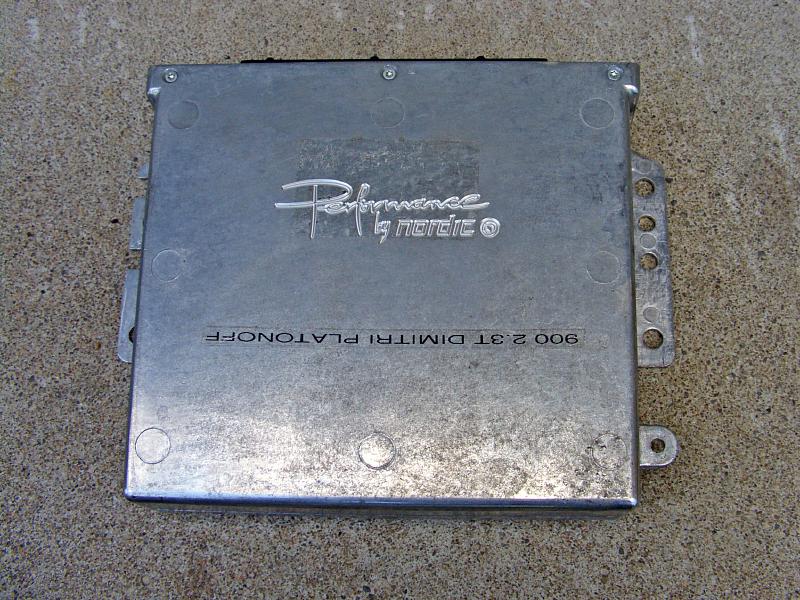

Here's a custom Nordic stage4 ECU I'm using with my freshly built 2.3L

engine.

|

|

| 10.07.2006: ECU harness |

|

Install the ECU (if you had it removed) and connect the wiring harnesses.

|

|

| 10.07.2006: Fuel lines |

|

Re-connect the fuel lines, the fuel tank vent line to the throttle body

and the EVAP valve harness.

|

|

| 10.07.2006: Cruise control |

|

Install the cruise control unit (two plastic 10 mm nuts).

|

|

| 10.07.2006: Throttle cable |

|

Attach the cruise control and accelerator cables to the arm on the throttle

body. Bolt on the brake booster vacuum line.

|

|

| 10.07.2006: MAP |

|

Connect the vacuum hose and the cable to the manifold pressure sensor

(this picture shows the strut bar installed already).

|

|

| 10.07.2006: Lower rad hose |

|

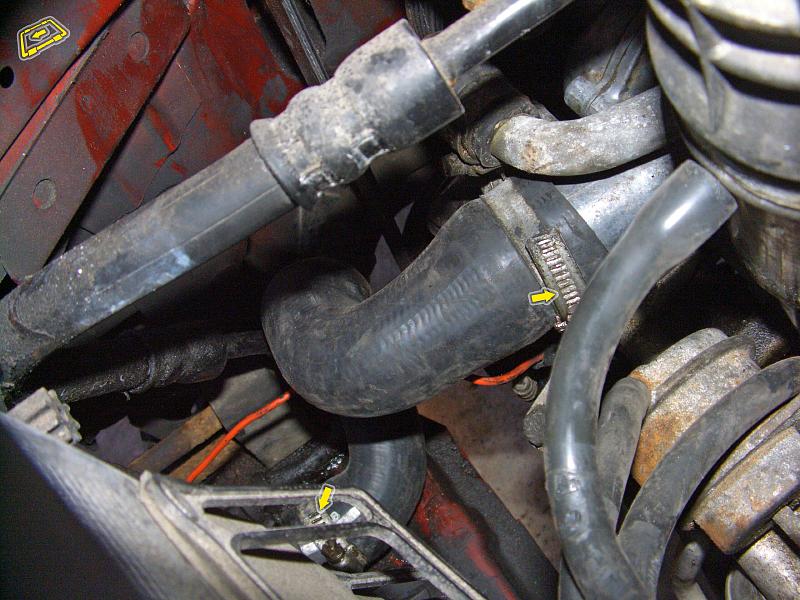

Install the lower radiator hose. I'm using a newer style nose here,

since it needs to clear the turbo hose to the cross-flow intercooler.

|

|

| 10.07.2006: Radiator hoses |

|

Attach the remaining coolant hoses: two heater core hoses, upper radiator

hose, upper and lower expansion tank hoses.

|

|

| 10.07.2006: Intercooler hose |

|

Connect the intercooler inlet hose to the compressor housing on the turbo.

Tighten the clamps well.

|

|

| 10.07.2006: Delivery pipe |

|

Install the delivery pipe from the intercooler to the throttle body.

Tighten the 13 mm bolt that holds it to the engine head.

|

|

| 10.07.2006: Downpipe |

|

Bolt the downpipe to the turbo and screw in the O2 sensor (or both if you

have an OBD II car).

|

|

| 10.07.2006: Finished |

|

Complete the

transmission-related

steps, fill the fluids and install the battery.

|