|

| 18.06.2006: Head |

|

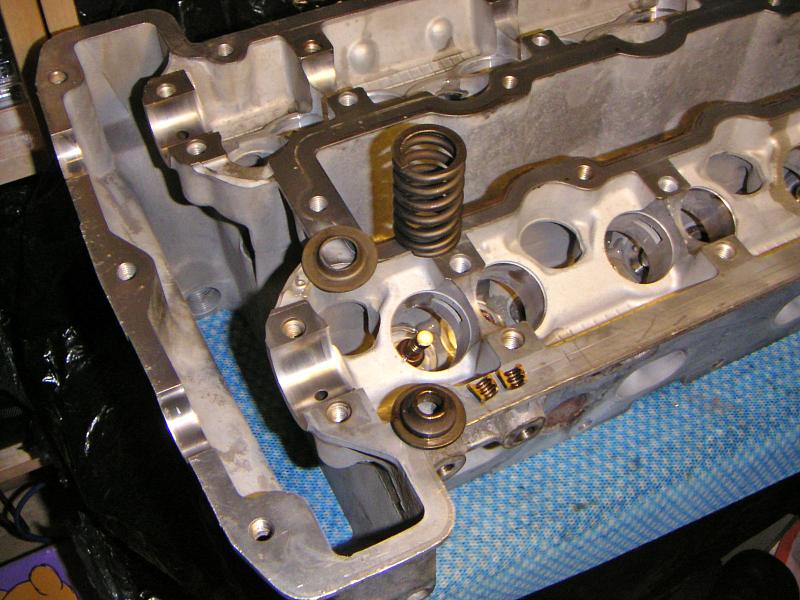

A freshly cleaned and polished head, just from an engine rebuilder.

|

|

| 18.06.2006: Valve seals |

|

Fresh valve seals go in first. Dip them in oil before installing.

|

|

| 18.06.2006: Tapping in |

|

A seal just slides on the end of the valve guide. An 11 mm socket is a

perfect tool for tapping them on.

|

|

| 18.06.2006: Installed |

|

Close-up of a seal installed.

|

|

| 18.06.2006: Valves |

|

There are four valves per cylinder. The intakes are slightly larger.

|

|

| 18.06.2006: Springs and washers |

|

The spring is sandwiched between two washers. The upper washer has a conical

collar wrapping around two collets that hold the valve stem.

|

|

| 18.06.2006: Getting ready |

|

The valve is in the socket, the rest is ready to follow. A dab of

grease on the inside of the collets will make them stick to the valve stem

and ease the installation.

|

|

| 18.06.2006: Valve spring compressor |

|

Install the lower washer, the spring and the upper washer.

Use a spring compressor to clamp the spring against the valve.

|

|

| 18.06.2006: Compressed |

|

When the spring is compressed, there's just enough room to insert the

collets using a pair of thin curved needle-nose pliers. Here's when

the grease on the collets comes in handy.

|

|

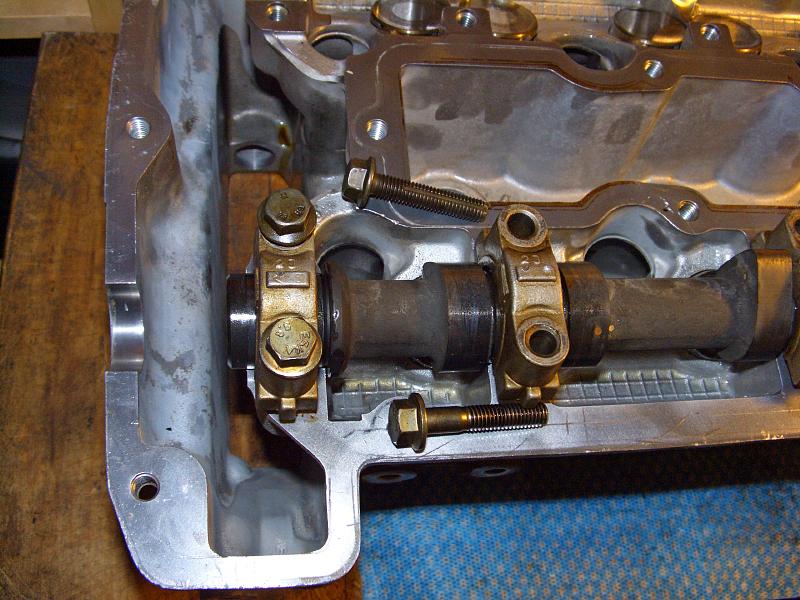

| 18.06.2006: Bracket |

|

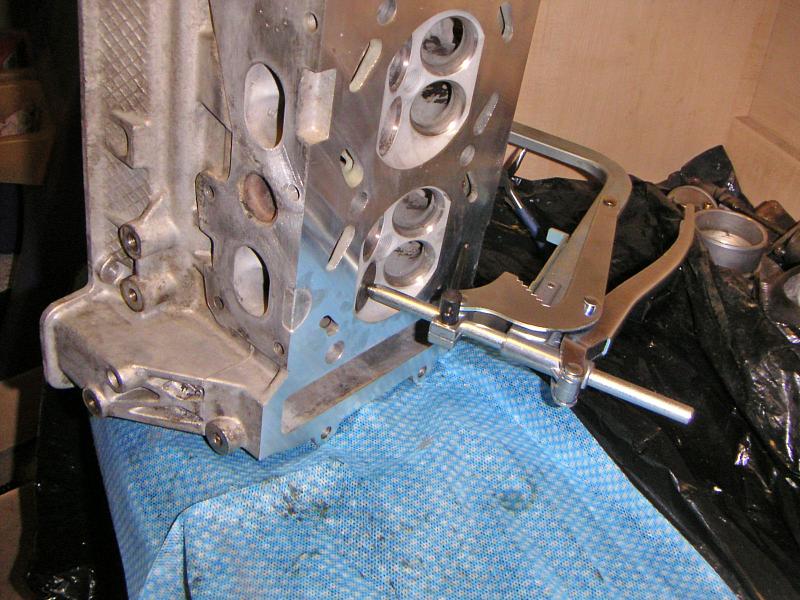

The universal spring compressor I got from an auto parts store could not

reach far enough, so I had to improvise by making this U-shaped bracket.

The walls around the spring should be protected from scratches since they

act as sealing surfaces for hydraulic tappets.

|

|

| 18.06.2006: Measurements |

|

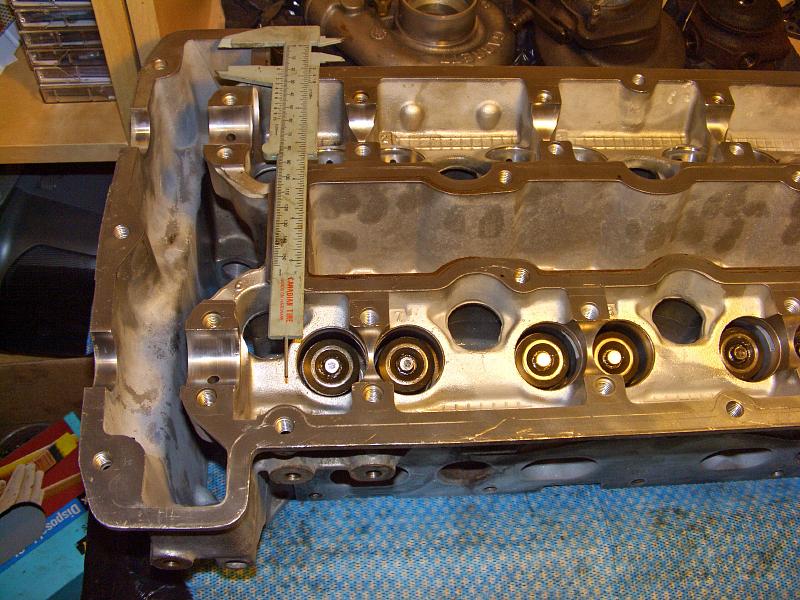

Measure the depth from the camshaft bearing surface to the valve stem.

It should be between 19.5 and 20.5 mm.

|

|

| 18.06.2006: Tappets |

|

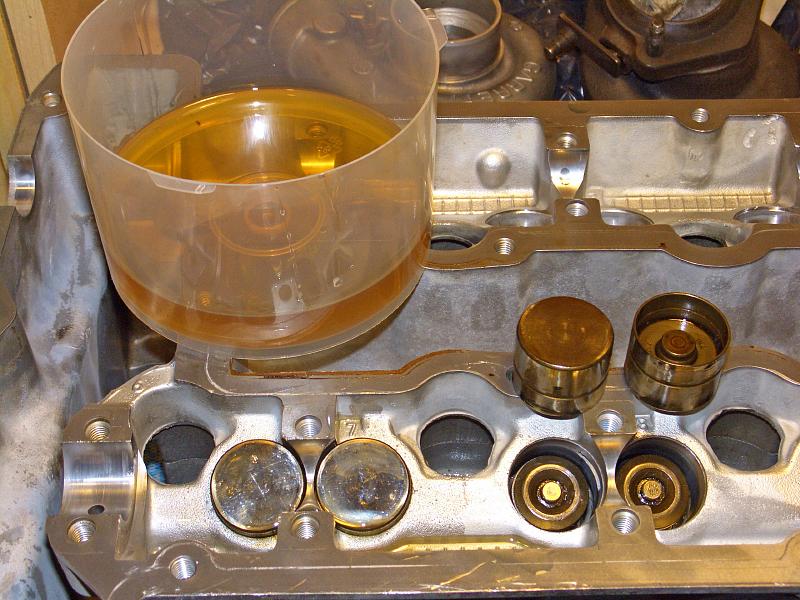

Install the hydraulic tappets. Give them an oil bath before putting

them in.

|

|

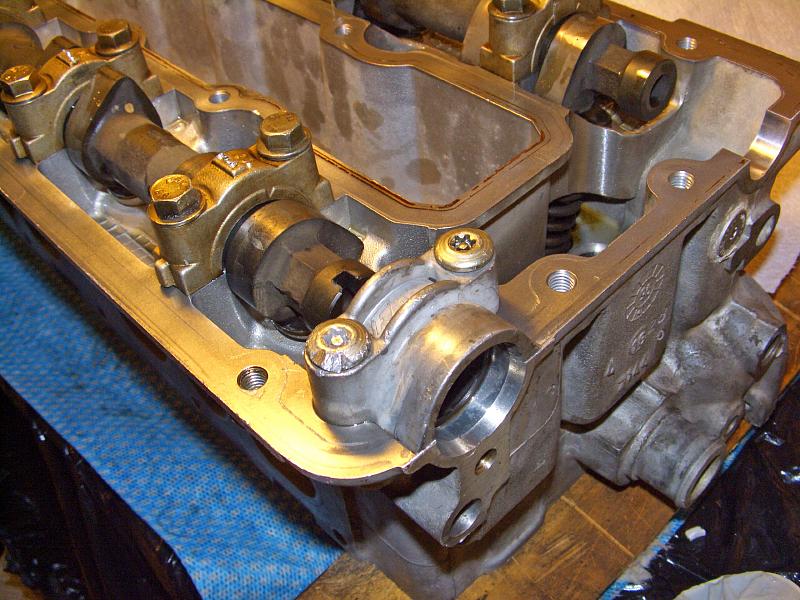

| 18.06.2006: Camshaft |

|

The camshaft bearing caps are numbered, but have rather bizarre markings.

My rebuilder marked them in a different fashion that was easier to read.

Put the head on wooden blocks so the valves won't be hitting the desk.

Lubricate the camshaft and put it in.

|

|

| 18.06.2006: Bearing caps |

|

Lubricate the bearing caps before they go in. The inner side bolts on the

four caps above the cylinders have oil passages in them.

|

|

| 18.06.2006: Tightening |

|

Tighten the bolts to 11 ft-lbs, starting with the cap closest to the cams

pressing down on the tappets (12 mm socket). Install the second camshaft.

|

|

| 18.06.2006: Side cover |

|

Attach the cover over the distributor cap hole (on turbo engines).

|