|

|

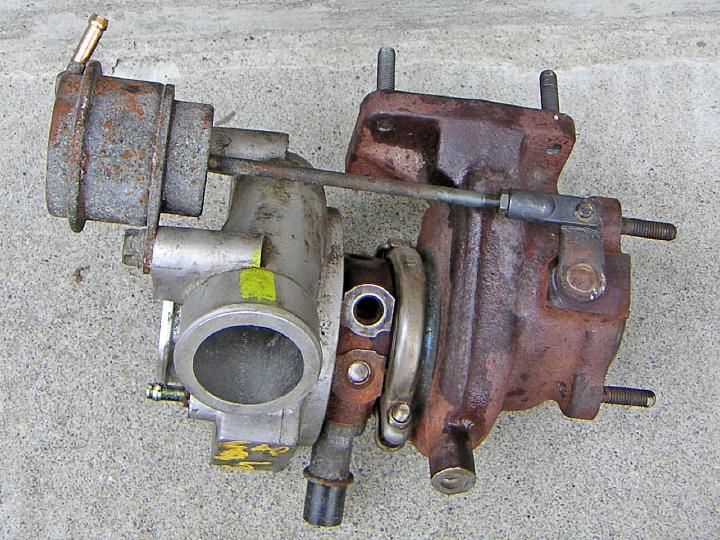

Turbocharger upgrade on a 1996 Saab 900. The stock Garrett T25 turbo is

being replaced with a Mitsubishi TD04 turbo found on Aero and Viggen models.

The procedure will be more or less similar for all Saabs using the B204-B235

engine family. This article describes the installation only, for turbo

removal instructions and more information refer to

this document.

If you're impatient, here's the answer everyone keeps asking about:

YOU DO NOT NEED NEW OIL OR COOLANT LINES!

That's right, you can reuse your existing oil and coolant lines as long

as they are in a good condition: not plugged, bent or cracked.

If your replacement turbo comes with new lines - good for you.

If not, don't bother

trying to source OEM lines or waste the money on the custom ones. All

you need is two M12 banjos and four copper washers with a ½"

inner diameter hole.

If you want details, here's a more detailed explanation on oil and coolant line

compatibility.

There are four

lines between the engine and the turbo -- two oil and two coolant passages.

- The oil feed line goes from the oil filter housing to the top of the

turbo. The banjo bolts have an M14 thread on the engine side and M12 thread

on the turbo. Ideally, you should use a new line when installing a turbo,

or at least clean the old one from sludge and deposits.

- The silicone oil return hose goes from the bottom of the turbo to the

oil pan. Both turbo and the engine side ports are noticeably narrower on the

TD04/GT17 compared to T25, and the T25 pipe doesn't bolt onto the TD04.

However, if you're upgrading to TD04, it's possible to find a smaller-sized

hose that would fit tightly on the thicker stock oil pan port and hold onto

the smaller pipe coming out of the TD04 with a help of a good clamp. A

stock hose that comes with TD04 is stretchy enough to fit on the thicker

pipe on B204L.

- The lower coolant line goes from the front of the turbo to the water

pump, except for B204L where it's connected to a port under the 4th cylinder.

The former version uses a banjo with an M12 thread on the engine side, the

latter has M14. The turbos are an ever bigger mess: the TD04 has an M12

thread, the T25/GT17 have M14, and the older T25 from the 1990-1993 9000s

have an odd thread of M16.

- The upper coolant line goes from the rear of the turbo to the upper

left side of the engine, near the upper radiator hose. The banjo

bolts have an M14 thead on the engine, M14 thread on T25/GT17, and M12

on TD04. If you're upgrading to TD04 and don't have matching lines, you can

use your stock lines with a 14 mm hole, just find a pair of wider copper

washers and put them on 12 mm banjo bolts that go into TD04.

Once again, a summary on the lines. If you're upgrading to TD04 from a T25 or GT17,

your life will be easier if you get two M12 banjo bolts and proper coolant

lines with 12 mm holes on the turbo side. These parts exist for B205/B235

(upper #9182460, lower #9174947), but with B204L you're out of luck, because

you need a lower line that goes to the port under the fourth cylinder, and a

version of such line with a 12 mm hole does not exist. Either way, if you

find yourself missing the lines, use your old ones with wider washers on M12

banjos, just tighten them well. The oil feed line will fit as is (although

it's often recommended to use a new one). The silicone oil return line from

GT17 fits fine, a car with T25 will need a narrower hose to replace the

stock one.

When upgrading from T25, you also need a new turbo inlet pipe and a manifold

stay. On a Trionic7 car with a GT17, the stock inlet pipe will fit, but the

car would still benefit from an upgraded high flow pipe.

Tools and supplies:

- 13 mm wrench and socket (downpipe and turbo nuts);

- 12 mm wrench and socket (banjo bolts);

- Torx T30 socket (turbo inlet pipe);

- 8 mm socket (shield screws);

- 7 mm socket (hose clamps), or flat screwdriver;

- large pliers (oil return hose clamps);

- torque wrench;

- ratchet handle;

- ramps or jacks and stands;

- new copper washers for all banjo bolts;

- new turbo to manifold gasket;

- turbo inlet pipe (when upgrading from a T25);

- inlet pipe clamp (when upgrading from a T25);

- manifold stay (when upgrading from a T25);

- thinner oil return hose (when upgrading from a T25);

- four ½" copper washers (if using T25/GT17 lines);

- two M12 banjo bolts;

- fresh oil and coolant.

|

| | 05.11.2005: Inlet pipe | |

A beautiful stainless high-flow turbo inlet pipe custom made by Nick

Taliaferro of genuinesaab.com.

|  | | 05.11.2005: Supplies | |

New seals, washers, clamps and a new turbo stay (my new turbo

was missing it).

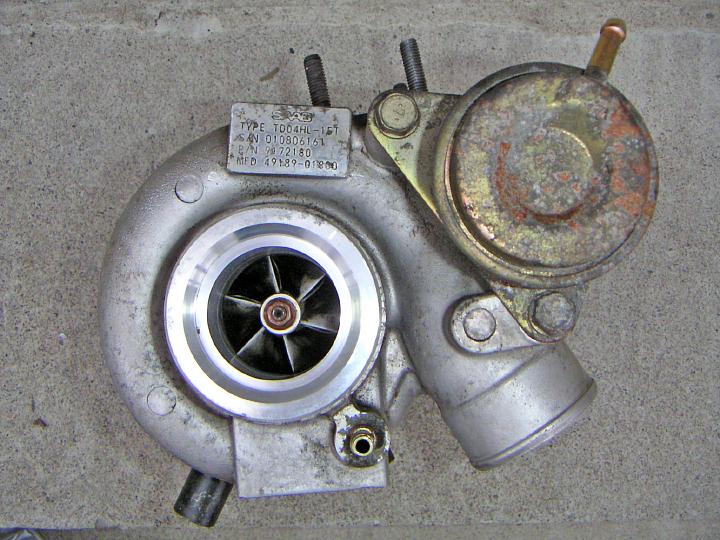

|  | | 05.11.2005: Turbo | |

The replacement turbo.

|  | | 05.11.2005: Turbo | |

It came from a 2002 Viggen.

|  | | 05.11.2005: Turbo | |

The full designation is TD04HL-15T.

|  | | 05.11.2005: Turbo | |

The exhaust manifold and downpipe flanges are the same as on T25, so

the turbo will bolt right on.

|  | | 05.11.2005: Exhaust manifold | |

Put the turbo on the car with a new manifold gasket, and secure it with

a nut or two. Don't tighten it yet to allow some movement until you connect

all the lines.

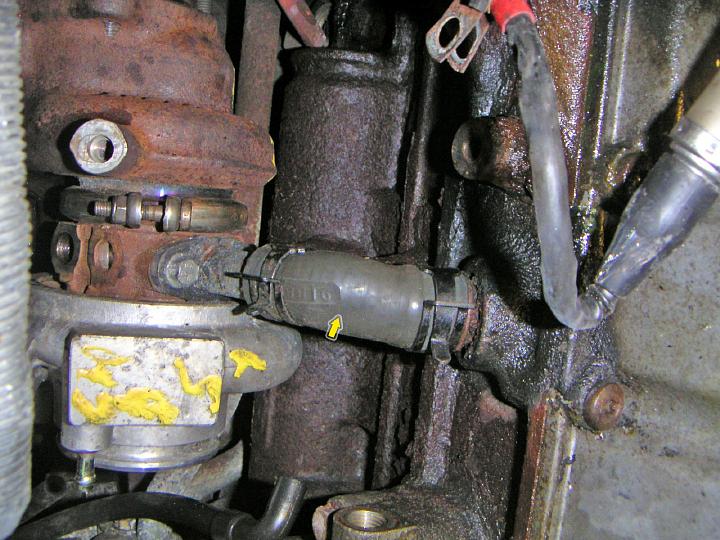

|  | | 05.11.2005: Oil return hose | |

Install and clamp the oil return hose. If you're lucky to have the hose

that comes with TD04, it should stretch to fit onto the thicker pipe on

the B204L engine.

|  | | 05.11.2005: Oil | |

Fill the turbo with engine oil and make sure it spins freely.

|  | | 05.11.2005: Oil line | |

Install the oil feed line.

|  | | 05.11.2005: Washers | |

12 mm TD04 banjo bolts are too small for 14 mm holes in stock coolant lines.

If you can't get proper lines, you can work around using oversize copper

washers. ½" drain plug washers will do.

|  | | 05.11.2005: Lines | |

Put bigger washers on both sides of the line fitting. When tightening those

later, apply enough torque to crush both washers. Take extra care to make

sure the bolts are centered inside their holes.

|  | | 05.11.2005: Coolant line | |

Attach the lower coolant line.

|  | | 05.11.2005: Coolant line | |

Attach the upper coolant line.

|  | | 05.11.2005: Manifold nuts | |

Bolt the turbo to the exhaust manifold (18.5 ft-lbs). Tighten all

banjo bolts.

|  | | 05.11.2005: Turbo stay | |

Install the turbo stay bar. Do not forget to attach the O2 sensor clamp.

|  | | 05.11.2005: Downpipe | |

Connect the downpipe to the turbo and tighten the nuts.

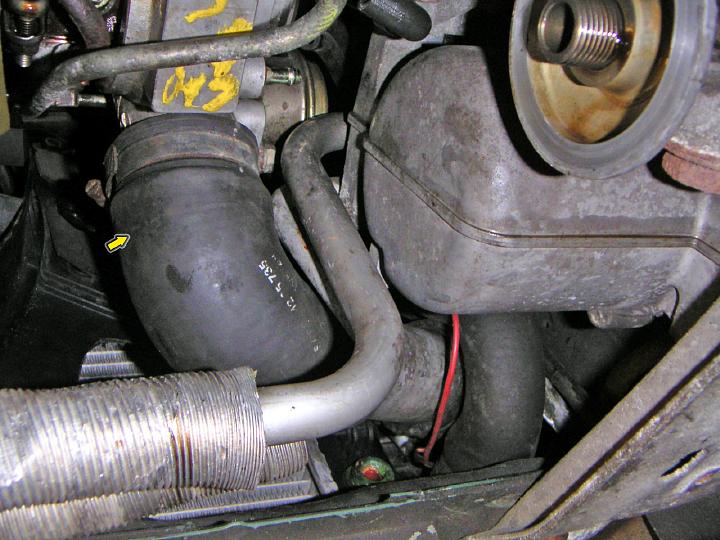

|  | | 05.11.2005: Intercooler hose | |

Attach the intercooler hose to the compressor housing outlet.

|  | | 05.11.2005: BPC line | |

Install the turbo inlet pipe, tighten the clamp and fit BPC hoses.

|  | | 05.11.2005: Intake pipe | |

Install the rubber elbow between the air box and the turbo inlet pipe.

|  | | 05.11.2005: Vent hose | |

Fit the crankcase vent hose. Some installations will have a barb for it,

I had to improvise. On this picture, the hose appears to be rather close

to the manifold, while there's actually quite a bit of distance. Still, a

heat resistant hose wouldn't hurt.

|  | | 05.11.2005: Bypass valve | |

Attach the bypass or dump valve, whichever your car has. Fit the oil filter,

fill oil and coolant, check for leaks from the banjo bolts on the turbo.

Before starting the car, crank it with a DI cassette plug disconnected and

fuel pump fuse out to ensure some oil flow through the turbo.

|

[return to index]

|

|