|

| 18.12.2004: The seat |

|

Here's the seat after I brought it home. You can see that the left bolster

surface is worn badly and has a huge hole in the middle.

|

|

| 18.12.2004: Head support sleeves |

|

First, remove the headrest and its support sleeves. Insert a screwdriver

a couple of centimeters down along the sleeve, press a tab and pull the

sleeve out.

|

|

| 18.12.2004: Staples |

|

On the bottom of the seat back, there are five staples that hold the ends

of the upholstery together. The staples are rather thick, you need two

pairs of needle nose pliers to handle them.

|

|

| 18.12.2004: Tension rod |

|

After the staples are gone, pull the fabric apart slightly and disconnect

the tension rods from the seat frame (there are two of them).

|

|

| 18.12.2004: Lumbar knob |

|

Remove the lumbar support knob. It comes right off if you give it a good

pull.

|

|

| 18.12.2004: Inside out |

|

Starting from the bottom of the seat, turn the edges of the skin inside

out and pull it upward to remove from the frame.

|

|

| 18.12.2004: More staples |

|

You will encounter more staples on your way. They connect the tension rods

to the thick wires attached to the seat frame.

|

|

| 18.12.2004: Last staples |

|

The last couple of staples at the next seam, and the seat cover is

free. Memorize the locations of the staples, you will have to put them

back later.

|

|

| 18.12.2004: Rear view |

|

This is how the lumbar adjustment mechanism looks like.

|

|

| 18.12.2004: Leather skin |

|

The skin is finally removed from the seat. Looks rather untidy.

|

|

| 18.12.2004: The seat |

|

The seat without its backrest upholstery. If your seat heaters do not

work, it's a good time to inspect the heating pads for torn wires (they

are the two grey squares in the middle).

|

|

| 18.12.2004: Seams undone |

|

I'm only replacing the front surface of the seat, so the back remains

untouched. Undo the seams and note how everything was put together,

including the tension wire.

|

|

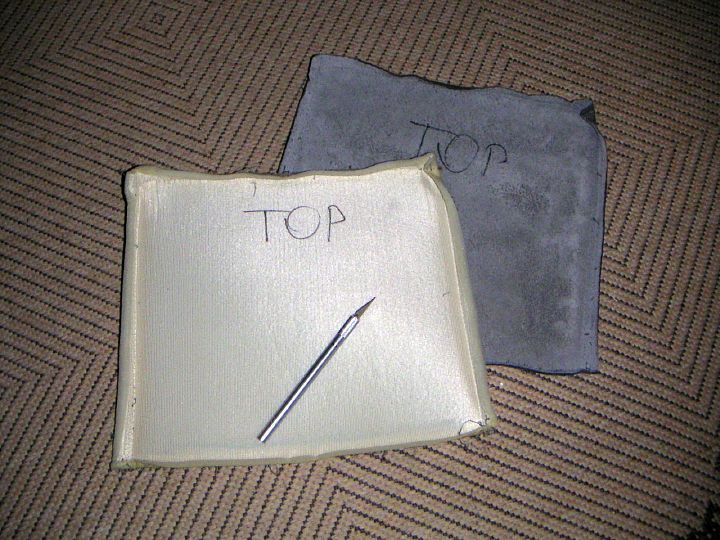

| 18.12.2004: Layers |

|

It helps to sign the parts on the back. The original upholstery consisted

of two layers: the leather top and the foam backing.

|

|

| 18.12.2004: Ribbons |

|

These ribbons work as sleeves for the tension wire. Ironing them should help

later when you will be sewing the fabric back together.

|

|

| 18.12.2004: Fabric |

|

Here's some thick matching upholstery fabric from

BouClair. We bought a bit more

in case we'll need to do the other seats in the future.

|

|

| 18.12.2004: Cut to shape |

|

Use the old pieces of leather to cut the fabric to the desired shape.

|

|

| 18.12.2004: Singer |

|

An old trusty sewing machine.

|

|

| 18.12.2004: Thread |

|

A spool of strong unholstery thread.

|

|

| 18.12.2004: Layers |

|

We did not want to reuse the old smelly foam backing, so we used a layer

of polyester fiber-fill covered with thin fabric.

|

|

| 18.12.2004: Helga |

|

The essential element of the whole adventure. Helga agreed to help

out despite having a cold and a sore throat.

|

|

| 18.12.2004: Stitching |

|

It is a two-step process. First you sew the upholstery fabric to the

backing, and then stitch the pieces to each other with the tension wire

sleeves on the back.

|

|

| 18.12.2004: Front complete |

|

Here's the front section finished. Do not forget that strip at the bottom

with a wire on it.

|

|

| 18.12.2004: Back side |

|

Now you need to attach the new front section to the leather back.

|

|

| 18.12.2004: Hand stitching |

|

I'm doing it by hand, using the perforation of the old seams in the

original leather parts.

|

|

| 18.12.2004: Dmitry |

|

It took me over an hour to do it the right way, but now I can brag that my

car has "hand-stitched leather" ;). And make that "sport seating

surfaces" too.

|

|

| 18.12.2004: Top finished |

|

Here's the renewed skin finished, waiting to be put back on.

|

|

| 12.06.2005: Bottom |

|

The bottom is much easier, it is smaller, and there are less staples.

|

|

| 12.06.2005: Undone |

|

The only difficult part is the plastic trim around the edge. It makes it

much harder to saw the side section on later.

|

|

| 12.06.2005: New fabric |

|

The fabric is cut to the shape of the old parts.

|

|

| 12.06.2005: Bottom finished |

|

The new parts are sewn together.

|

|

| 18.12.2004: Fitting the top |

|

Fitting is the reverse of the removal. Start with the top, fit the headrest

sleeves to hold the fabric and work your way down restoring the staples

and making sure the tension wires follow the grooves in the seat foam.

|

|

| 12.06.2005: Done |

|

The job is complete. The fabric fits the seat nicely. It also holds you

better in sharp turns and feels more friendly in very cold or hot weather.

|